High Volume Beneficial Use of Coal Combustion Residuals (CCR)

Typical beneficial use processes that utilize coal ash as a feedstock (for example, repurposing fly ash in concrete) are limited because “lower quality” CCR will typically not react with the calcium hydroxide released by the chemical reaction between cement and water to form additional cementitious products that improve the density and permeability properties of concrete. That is why typical CCR beneficial use processes are limited to using only Class F or Class C fly ash that meets the ASTM C618 standard.

For this reason the vast majority of the millions of tons of CCR in a typical pond or landfill either cannot be used or will require decades to be fully used as a non-structural filler in concrete.

Additionally, the presence of heavy metals and Naturally Occurring Radioactive Materials (NORMS) prevent safely repurposing CCR in a manner that does not simply propagate the owner’s liability and potentially exposes humans, pets, and nature to exposure.

These limitations mean most Beneficial Use projects will significantly exceed CCR permit timelines. At Tephra, this is simply unacceptable!

Tephra has a proprietary Thermo-Chemelectronic Decomposition Reactor that separates the CCR feedstock into its individual elements and then recombines them into more reactive forms.

Treating the CCR with our Reactor enables Tephra to utilize all typical forms of CCR in our green cement including fly ash, bottom ash, gypsum, slag, etc. (or any combination of these products).

Our Reactor also reduces heavy metals (such as arsenic, mercury, lead, etc.) from the CCR so Tephra’s beneficial use process is also safer for humankind and the environment we share.

Our Decomposition Reactor is a high throughput, high efficiency, zero emission, zero waste, zero residual process and is capable of processing up to 10,000 tons of CCR per day, per project. Repurposing CCR at this rate enables Tephra to completely eliminate its client’s coal ash storage facilities in a very short period of time!

Tephra owns a portfolio of proprietary formularies for manufacturing green concrete, but the development of the Decomposition Reactor is a major technological breakthrough which enables Tephra to manufacture a new and significantly improved version of green concrete (trademarked “GreenMix™”) that is an environmentally friendly, high-quality, high-strength, structural cement that complies with the encapsulation standards of 40 CFR Part 257, Subpart D.

After treating any typical form of CCR (fly ash, bottom ash, gypsum, slag (or any combination thereof) with our proprietary Decomposition Reactor it is incorporated into GreenMix at ~65% composite volume as a natural pozzolanic material.

The engineering properties of GreenMix are analogous to traditional high-strength concrete. However, traditional concrete requires the use of Portland Cement which is made in energy-intensive kilns that generate more than half a ton of carbon dioxide for every ton of product – a concrete process which is responsible for generating about 7% of global emissions.

Treating the CCR with our proprietary Reactor totally eliminates the need to incorporate Portland Cement so there are zero emissions associated with the production or use of GreenMix!

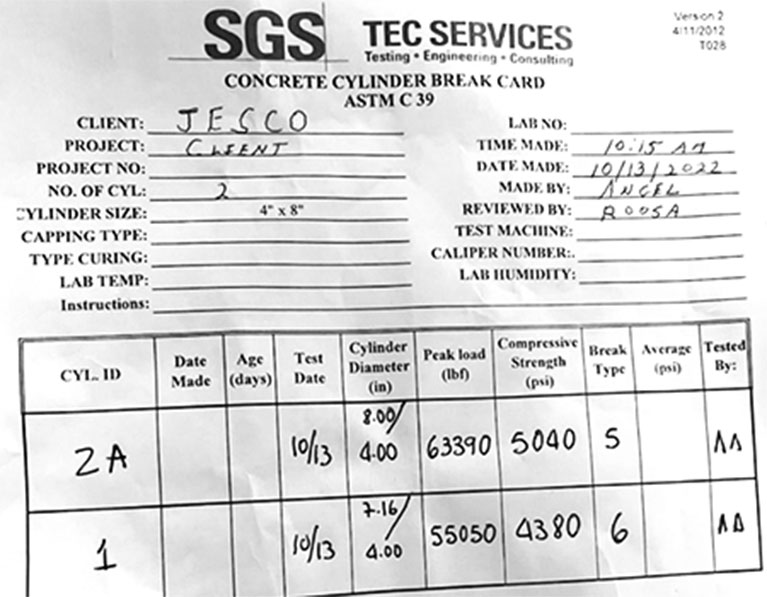

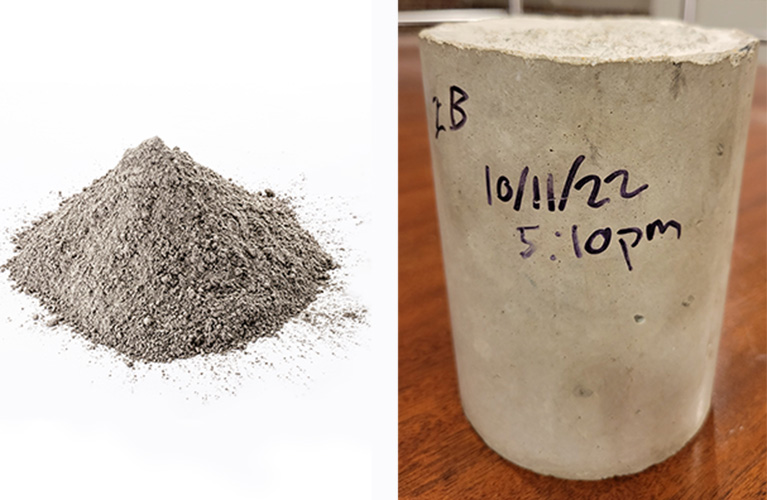

Pictured below is a cylinder of GreenMix Tephra manufactured (and poured at 5:10pm on 10/11/2022) from a utility client’s ponded CCR and the independent laboratory results of a 48-hour Cylinder Break Test.

As indicated, this cement attained a compressive strength of 5,040 PSI in only two days with no added strengthening measures (such as aggregate). Moreover, no Portland Cement was used in this cement thus there is no emissions of any kind were involved in the manufacturing process!

Treating CCR with Tephra’s proprietary Decomposition Reactor creates significant competitive advantages regarding sales and distribution channels as it enables GreenMix to be manufactured in several different commercial forms including a dry “Ready-Mix” which we market to regional concrete and cement distributors and to retail consumers via home improvement stores.

Tephra also manufactures GreenMix pre-cast structural building materials (such as wall panels, structural blocks, cladding, etc.) which we market to both domestic and international commercial and residential builders.

Any GreenMix materials that are not absorbed domestically are shipped (via JESCO’s marine barging division) to large-scale developments in the Caribbean and Saudi Arabia.

Tephra’s parent company (JESCO) has a marine division complete with barges and tugs of all capacities. It also has over forty-five years of worldwide experience utilizing dredging and pipeline (and conveyor) transport of CCR materials.

Moreover, JESCO has been safely and effectively performing CCR management projects since the 1970s and owns a fleet of “yellow-iron” heavy equipment necessary to perform multiple simultaneous projects at multiple sites.

These resources provide Tephra the capability to safely excavate, convey, and transport up to 10,000 tons of CCR per day per project without significantly increasing truck traffic on public rights of way.

If desired by its clients, Tephra is willing to make the upfront investment for the costs of establishing its GreenMix production plant on a client’s site so that its compensation is tied solely to CCR removal via GreenMix production plant on a client's site. Therefore, Tephra’s beneficial use process is risk free to the client at a guaranteed per-ton fixed price.

Moreover, our Beneficial Use solution – including the project schedule and commercial terms - is flexible to accommodate nearly any client preference and to assure that it does not compete with existing marketing contracts for production ash. Alternatively, at the client’s direction, we can absorb current production ash into our process so that no additional CCR ever needs to be ponded and the operating life of the power plant is extended indefinitely.

As for project flexibility, Tephra has the resources and financial ability to perform the project entirely turnkey. Alternatively, should our client prefer to use its existing civil contractors to perform the CCR dewatering, excavation, moisture conditioning, and conveying, then we are happy to focus solely on beneficially using 100% of the CCR in your pond or landfill.

Moreover, Tephra can perform its Beneficial Use process on a client’s site or offsite at the client’s direction.

Tephra’s Beneficial Use Value Propositions:

- Saves our client’s time.

- Saves our client’s money.

- Immediately decreases/eliminates our client’s liability.

- Repurposes all our client’s CCR for beneficial reuses within a short period of time (generally less than 5 - 10 years).

- Removes heavy metals from the CCR so Tephra’s beneficial use process is safe for humankind and the environment we share.

- Decreases future monitoring and compliance requirements.

- Remediates any contaminated water so that it can be repurposed for beneficial uses.

- Eliminates the footprint of our client’s ash impoundments so the sites can be repurposed for their highest and best use.